코팅 바의 종류

- 사용처가 어떻게 다른지 확인해보자.

Bar coater/ Alilox roll│OSG SYSTEM PRODUCTS., LTD│OSP

D-Bar is the OSG product with high precision and high efficiency based on the solid technology that has supported the world-wide manufacturing for years. We improved the traditional wire-bar (a kind of coating bar which wire wounded around a core bar) that

www.j-osp.com

Features of D-Bar

Feature 1

Free from wire cut or wire displacement.

The bottom of the groove is designed into a wide shape, so the clogging caused by the coating is reduced, and the bar is easier to clean. Long-term and stable coating performance can be expected to achieve.

Feature 2

Less clogging and easy to clean.

The bottom of the groove is designed into a wide shape, so the clogging caused by the coating is reduced, and the bar is easier to clean. Long-term and stable coating performance can be expected to achieve.

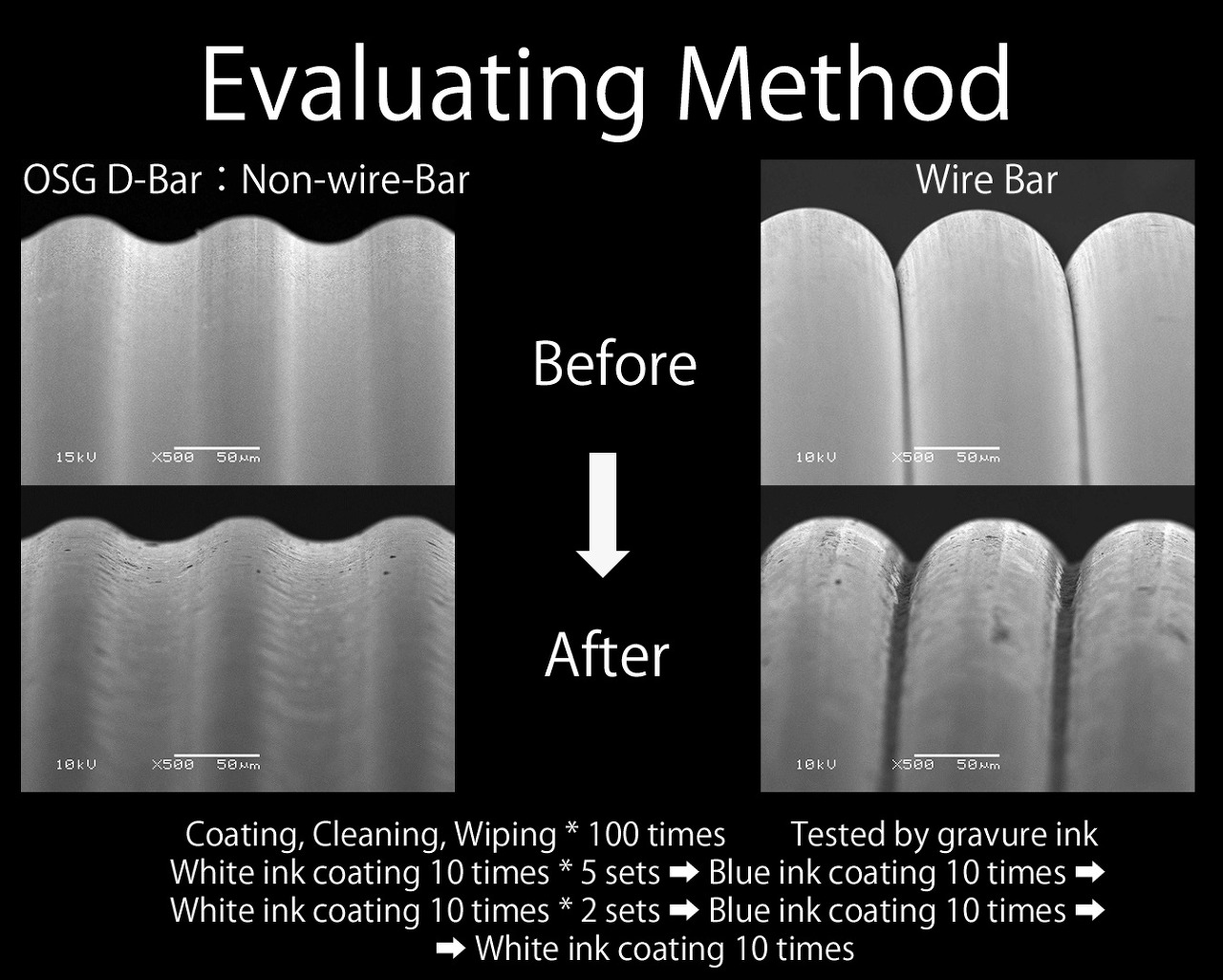

Test method: Test with ink. (gravure ink)

Coating, Cleaning, Wiping * 100 times

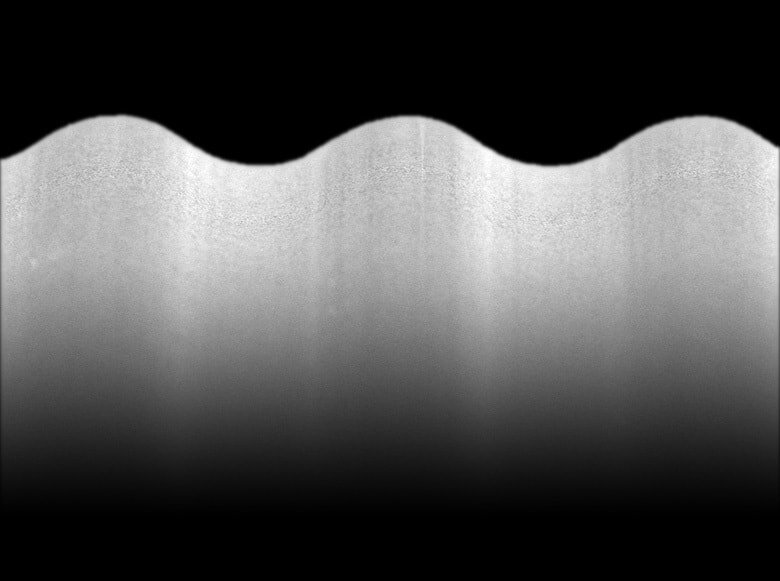

SEM (Scanning electron microscope) Comparison image

Feature 3

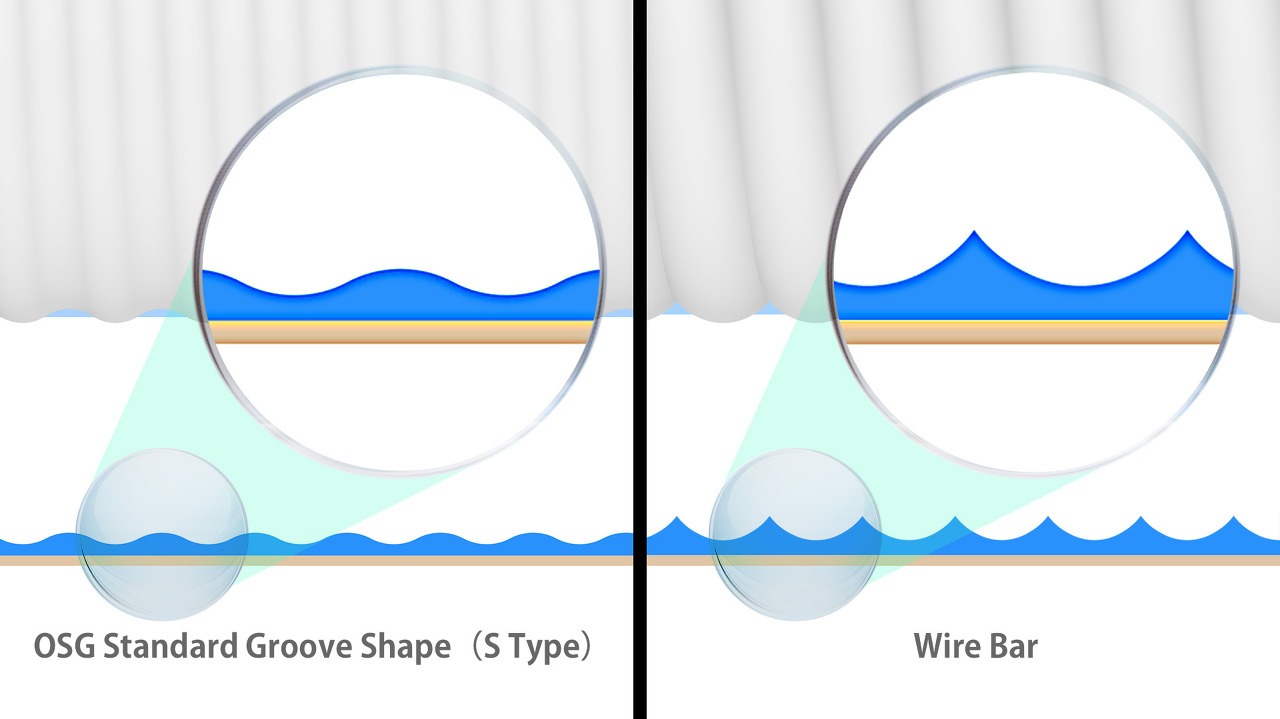

Excellent coating liquid leveling property.

The bottom of the groove is designed into a wide shape, so the coating leveling(smoothing) is excellent. Coating defects such as streaks and stains would reduce and the coating surface quality would be expected to improve.

Feature 4

a wide variety of groove shapes are available.

A wide variety of groove shapes would help improve the coating surface quality.

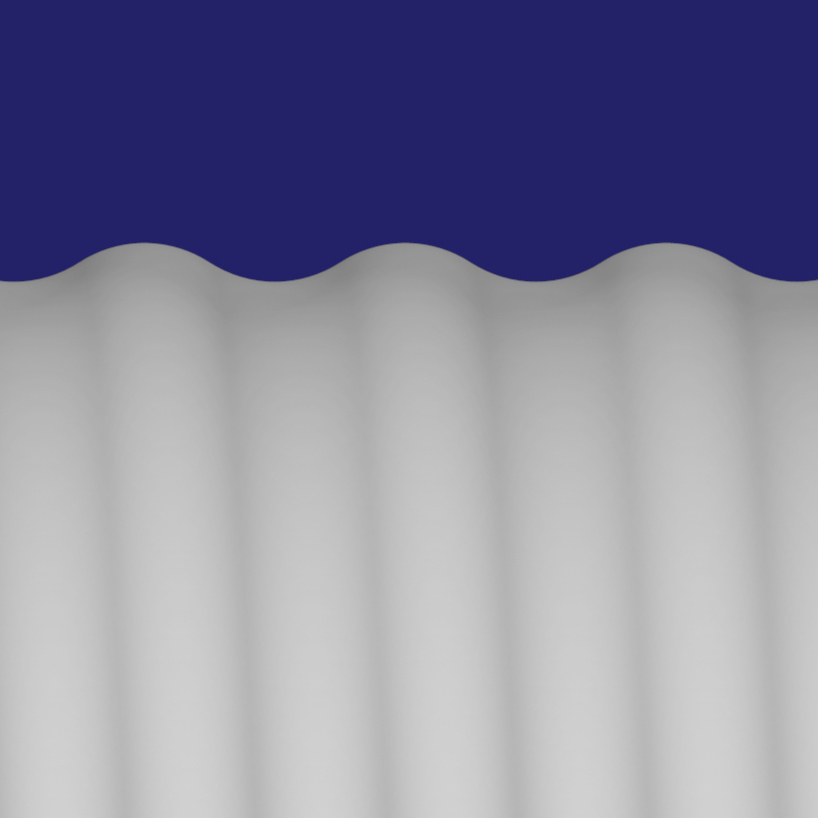

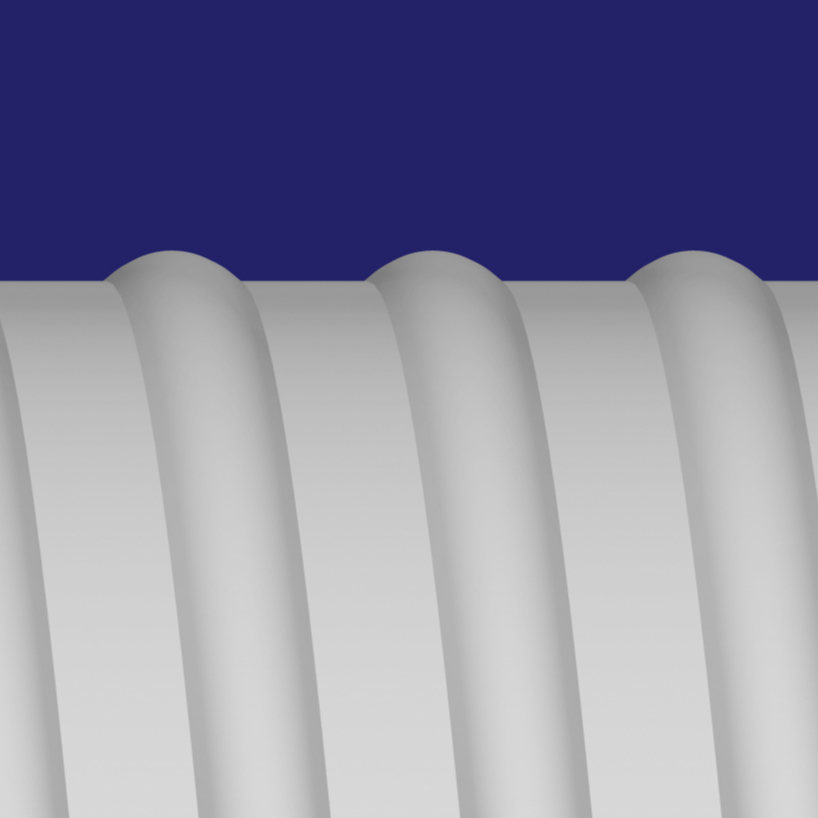

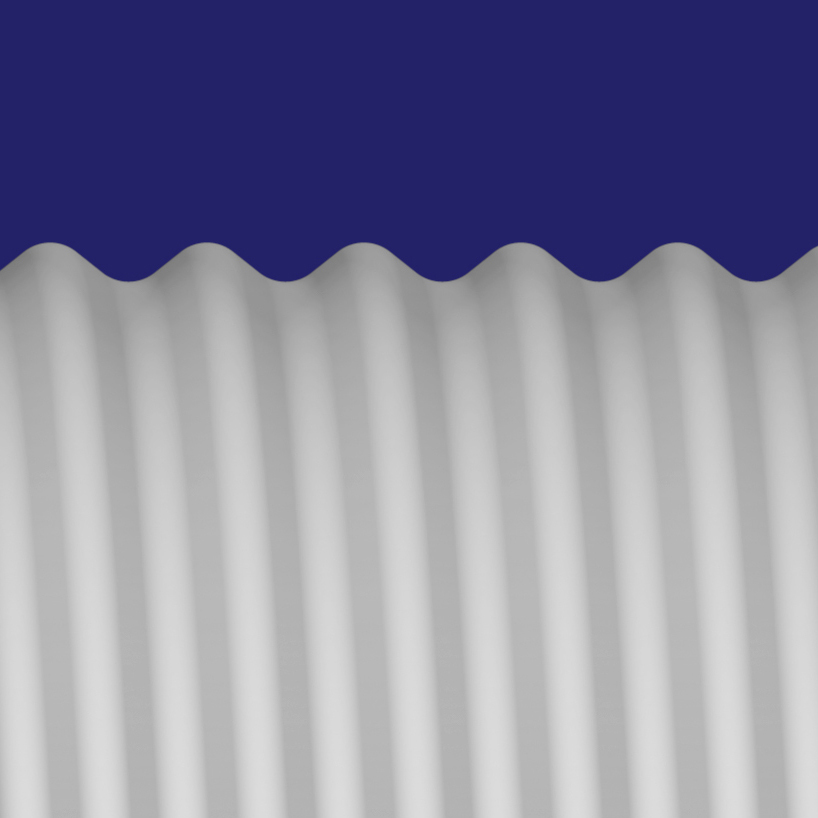

S-type

S-type is the standard groove shape of OSG Wireless Bar. The R shape of the top and bottom of the groove is designed to reduce the clogging problem.

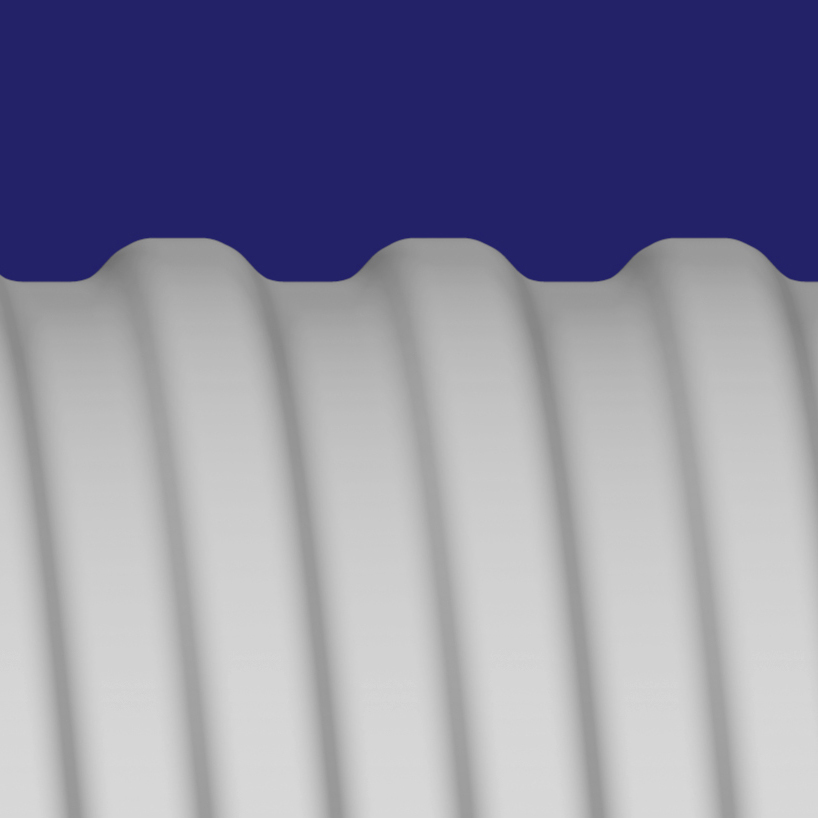

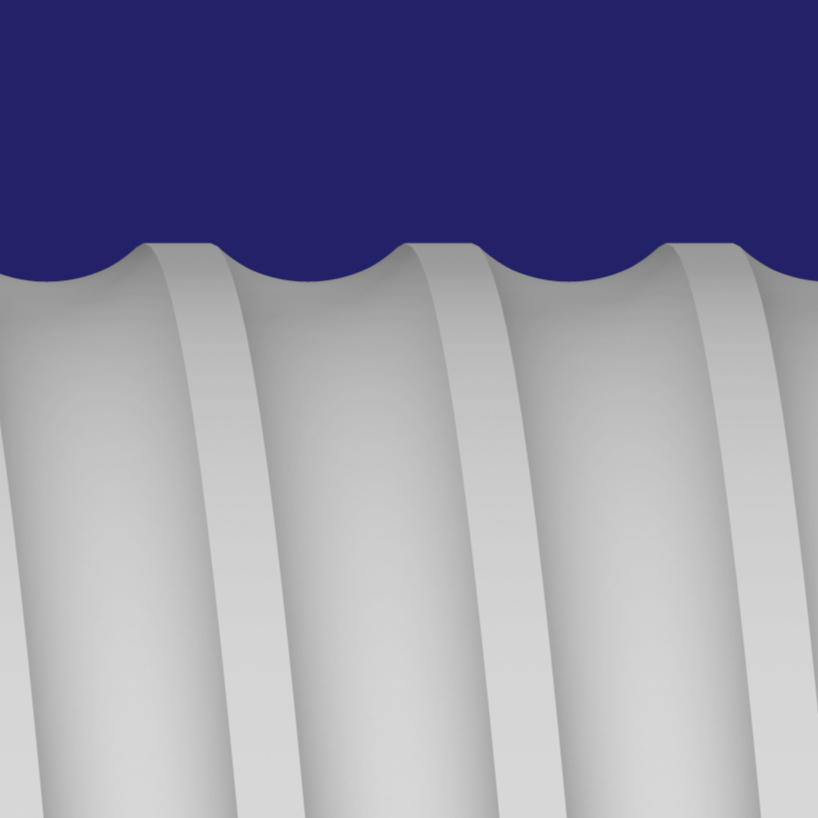

K-type

The bottom of the K-type groove is disigned to aim flat as to improve the coating leveling(smoothing). K-type is comparatively often used in the coating condition of high viscosity and large coating weight.

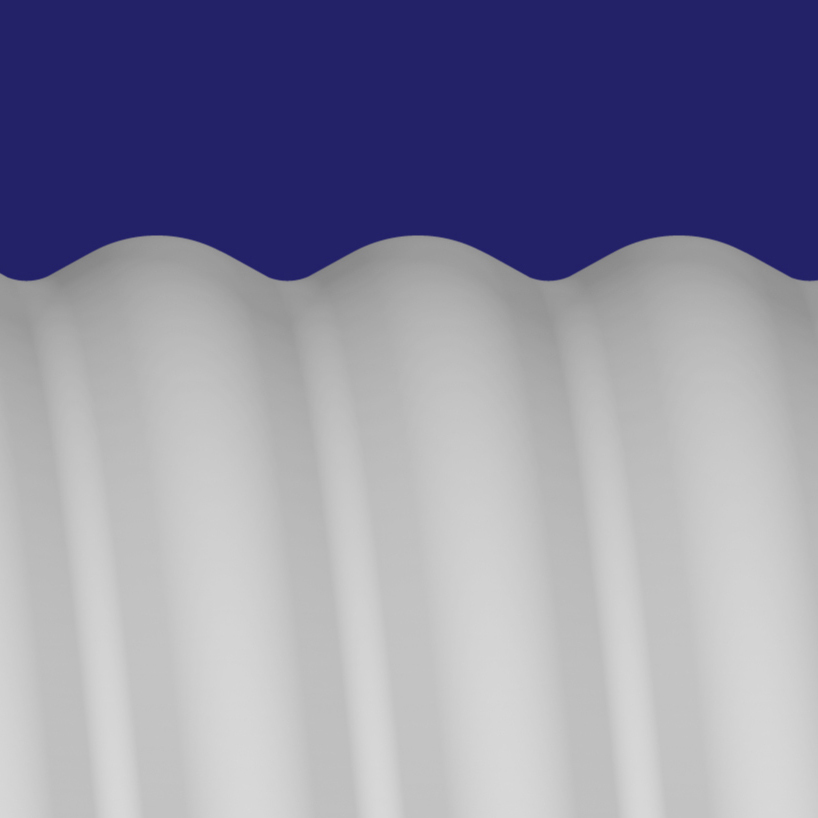

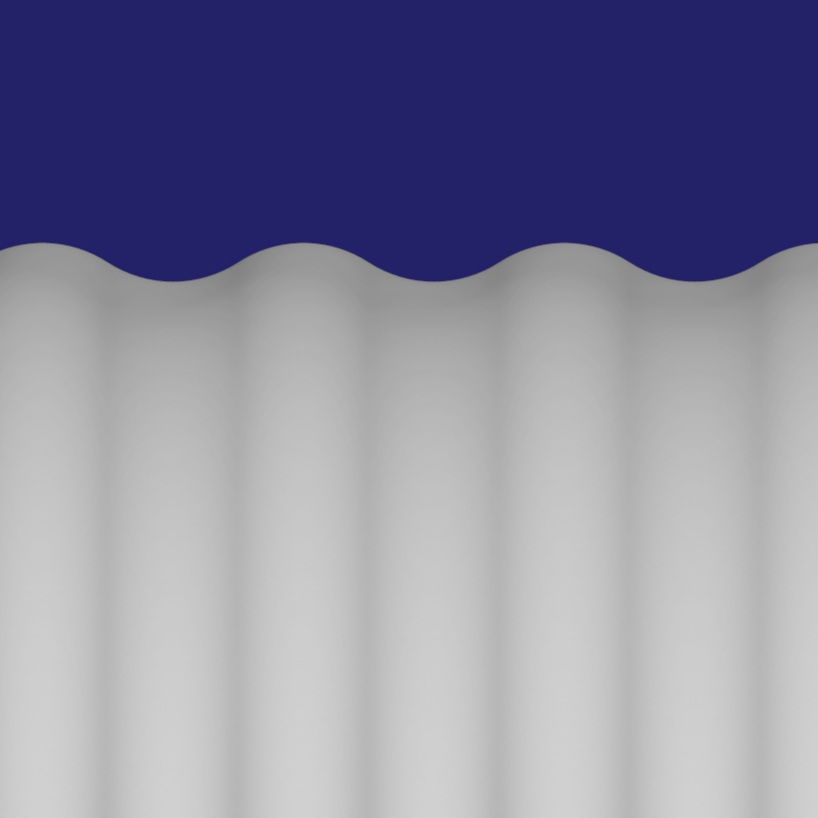

W-type

It is a specification aimed at reducing initial wear by providing a flat part on the top of the groove.

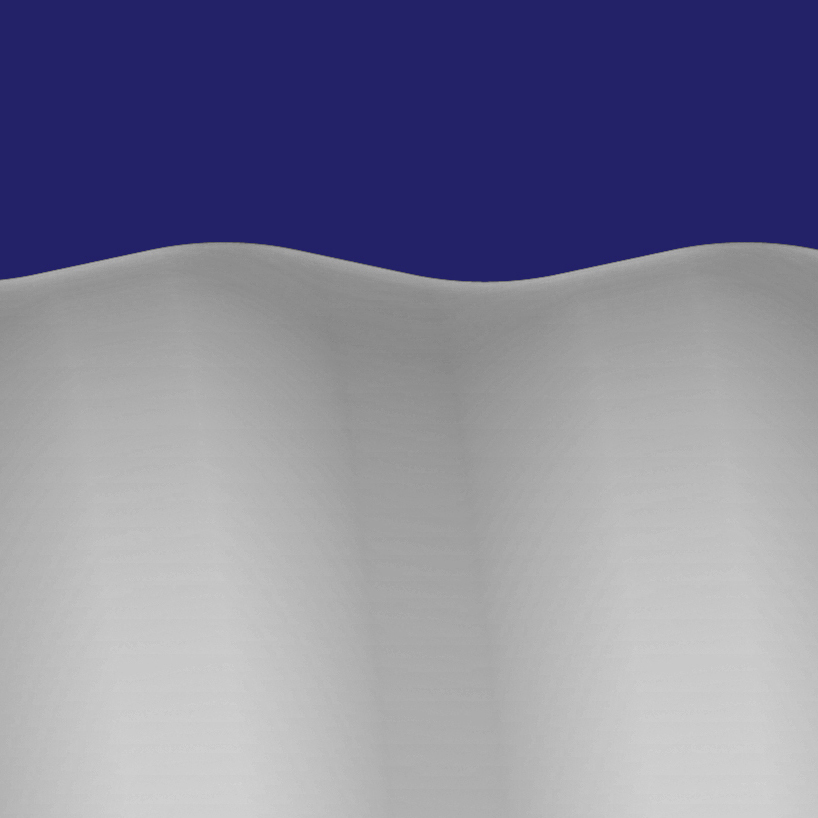

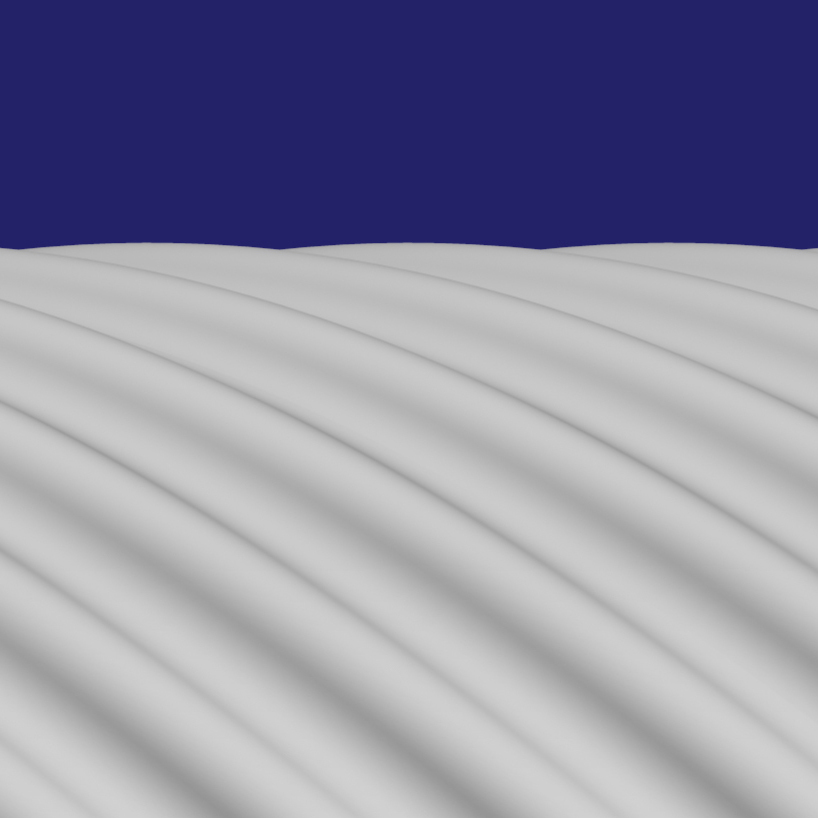

R-Max (RS) type

It is a specification aimed at reducing initial wear by increasing the R at the top of the groove compared to the S type. And also, improving the coated surface by increasing the contact point with the base material.

WP-type (Wide pitch)

It is a specification aimed at leveling the liquid by widening the pitch between the grooves.

NP-type (Narrow pitch)

This specification increases the number of points supported by the groove, such as when the base material is very thin or when tension is not too high.

M-type

Groove shape with a flat part at the top of the groove and R shape at the bottom of the groove.

0° (Ring)

The grooves are not spiral grooves but completely seperated with each other to prevent inclusion from the end of the bar.

Angled (3°~)

By forming an angle, this groove spec. aim to reduce pitch streaks and expect foreign matter to escape faster during application. Even if you use the S type and streaks remain, angle type would reduce and remove streaks.

'상식+ > 공부자료' 카테고리의 다른 글

| Science advances - 저자에게 요구하는 확인사항 (0) | 2023.01.05 |

|---|---|

| Major News in COMSOL Multiphysics® Version 6.1 (0) | 2023.01.05 |

| 보행자의 안전관리_2022 (0) | 2022.04.13 |

| 세계 최초로 구리의 산화 원리 밝혔다 (0) | 2022.03.24 |

| [영어 작문 수업 Day 1.] (0) | 2022.03.03 |